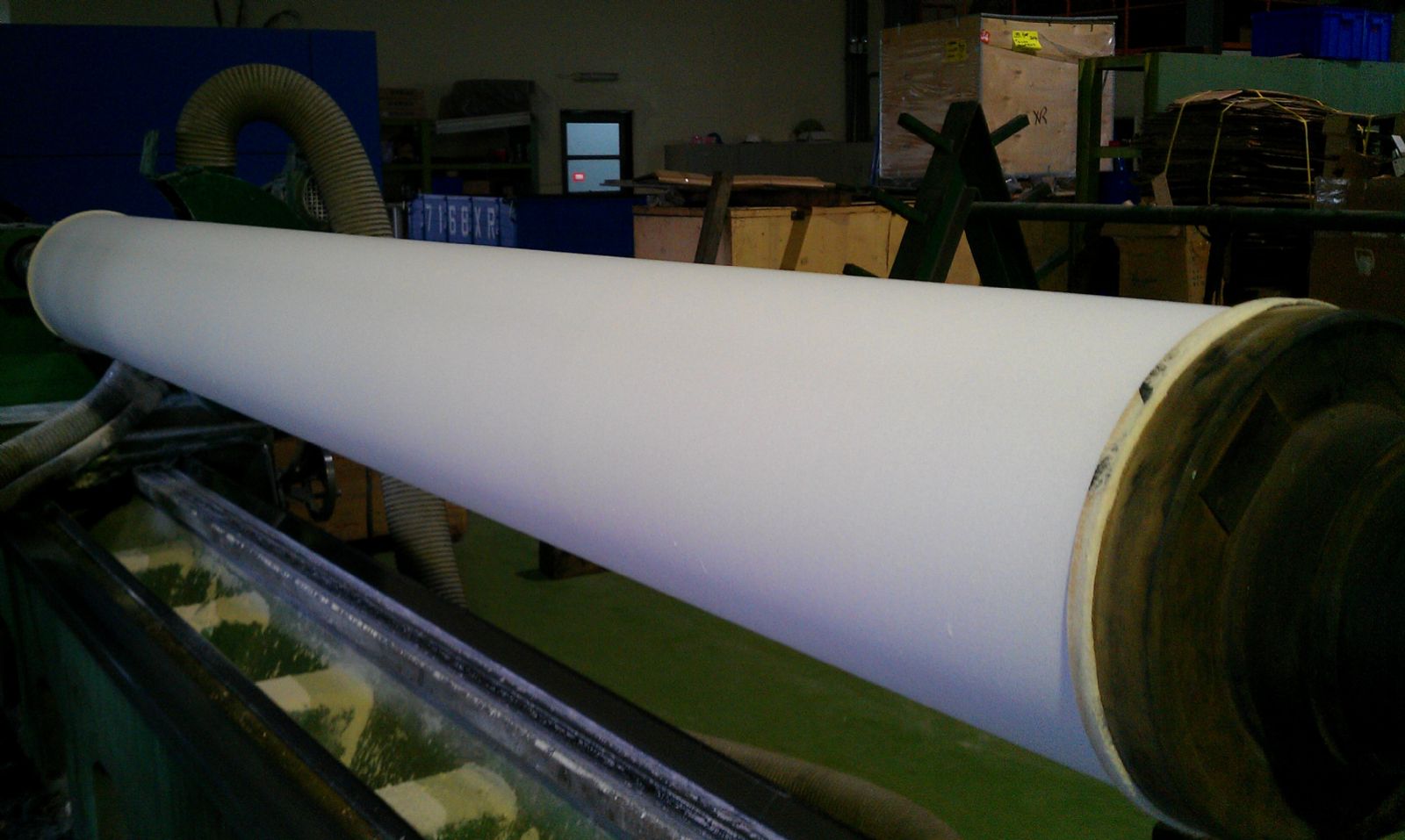

Ceramic Fiber Rolls

Non-Asbestos Furnace Roll - Ceramic Fiber Roll

In Annealing and Pickling lines of stainless steel plants require extremely smooth surface. The stainless steel sheets are first heated by the Annealing process. In this process, the sheets are heated up to 1200°C! At this temperature, the sheet becomes extremely sensitive to marks and scratches that are caused by normal steel furnace rolls. These steel rolls develop corrosion and rust, which would do critical damage to the quality of the stainless steel surface.

As a technology leader, ME have tested numerous materials, ceramic fiber rolls are proved to be the best for both high-quality and environmental-friendly purposes.

Benefits of Using ME Ceramic Fiber Rolls

► Longer rolls life-span against competitors - the average life-span of ME ceramic fiber roll can achieve to 60 days, including three times regrinding

In the event of your esteemed company might be interested in having a quotation, please kindly provide us with the following information: